¶ Thermal Simulator

The thermal simulator is a powerful tool that allows the well designer to calculate the temperature profiles for all strings and annular spaces in the subject wellbore for any number of production, injection and circulation scenarios, as well as a WCD scenario where only a subset of the wellbore strings is affected.

In this tab, the user can create new cases, calculate all cases or a subset of them, view summary information about the currently selected case, and view the results of some or all of the calculations.

¶ Add New Case

User defines the input parameters for a selected thermal case. The user can select one of the following modes:

- Production

- Water-Gas Injection

- Worst Case Discharge

- Circulating

- Transient Shut-In

Each mode has a set of required input parameters and those are defaulted to a set of predefined values. The parameters that are not required are grayed out.

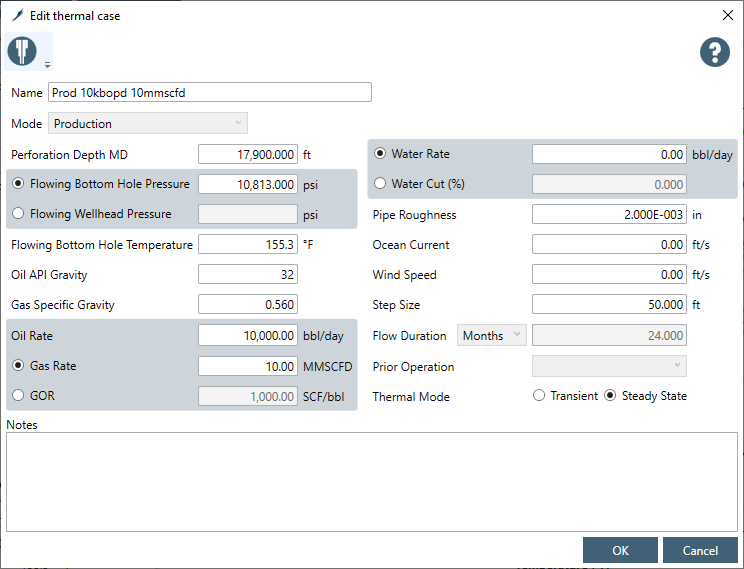

¶ Production

If the selected mode is Production then the form allows users to enter the parameters required to create a production load case. Following inputs are required for this load case:

- Perforation Depth MD: This input defaults to the bottom MD of the tubing from the casing program. User can edit this input to enter a different depth of perforations. This field cannot be empty.

- Flowing Bottom Hole Pressure: One of the pressures (1) Flowing Bottom Hole Pressure (FBHP) or (2) Flowing Wellhead pressure (FWHP) is required. Both fields cannot be selected. The default FBHP is the pore pressure at the perforation depth.

- Flowing Wellhead Pressure: Default flowing wellhead pressure is the seawater hydrostatic at the mudline.

- Flowing Bottom Hole Temperature (FBHT): This input defaults to the undisturbed temperature at the perforation depth. The Undisturbed Temperature profile in the Temperatures tab under The Well Module. User can edit this input. This field cannot be left empty.

- Oil API Gravity: Specific gravity of oil of the produced fluid is defaulted to 32. This can not be empty or zero when a non-zero oil rate is expected.

- Oil Rate: Oil flow rate is in bbl/day and can be zero for gas only production. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- Gas Specific Gravity: Specific gravity of gas of the produced fluid is defaulted to 0.56 (as Methane). This can not be empty or zero when a non-zero gas rate is expected.

- Gas Rate: Gas flow rate is in MMSCFD and can be zero for oil only production. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- GOR: Gas-Oil-Ratio in SCF/bbl can also be entered instead of gas rate. In this case oil rate can not be zero bbl/day.

- Water Rate: Water flow rate is in bbl/day and can be zero. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- Pipe Roughness: The default value for pipe roughness is 0.002 in. User may change this entry.

- Flow Duration: This parameter is the total flow period of the production operation. It may be entered in hours, days or months. This is a required input field and may not be left empty.

- Ocean Current: Heat transfer in the riser can be modeled with a non-zero ocean current. The default value is 0 ft/s.

- Wind Speed: Wind speed in ft/s is required for the section above the sea level to the rig floor. The default value is 0 ft/s.

- Step size: This denotes the step size (in ft.) used for segmenting the string. This parameter defaults to 50 ft. This field cannot be empty.

- Click OK to add the thermal operation or Back to go back to Add new thermal case window.

- Press Cancel to cancel out adding a new thermal operation or modifying the existing thermal case.

¶ Injection

If the selected mode is Water-Gas Injection then the form allows users to enter the parameters required to create a Water-Gas Injection load case. Following inputs are required for this load case:

- Surface Injection Temp: This parameter defaults to the surface temperature (in F) from the Undisturbed Temperature profile in the Temperatures tab under The Well. User can edit this input. This field cannot be left empty.

- Surface Injection Pressure: User should enter the injection pressure in psi. This field cannot be empty.

- Injection Depth MD: This is the depth at which the injected fluid will go in to the formation. This parameter defaults to the well TD.

- Gas Rate: Gas injection rate is in MMSCFD. For water only injection case, gas rate can be zero.

- Gas Specific Gravity: Gas specific gravity is defaulted to Methane specific gravity.

- Water Rate: Water injection rate is in bbl/day. Both gas and water injection rates can not be zero.

- Injection Fluid Density: The default fluid density is 8.33 ppg as for fresh water.

- Pipe Roughness: The default value for pipe roughness is 0.002 in. User may change this entry.

- Flow Duration: This parameter is the total flow period of the production operation. It may be entered in hours, days or months. This is a required input field and may not be left empty.

- Ocean Current: Heat transfer in the riser can be modeled with a non-zero ocean current. The default value is 0 ft/s.

- Wind Speed: Wind speed in ft/s is required for the section above the sea level to the rig floor. The default value is 0 ft/s.

- Step size: This denotes the step size (in ft.) used for segmenting the string. This parameter defaults to 50 ft. This field cannot be empty.

- Click OK to add the thermal operation or Back to go back to Add new thermal case window.

- Press Cancel to cancel out adding a new thermal operation or modifying the existing thermal case.

The added injection or production simulations can be viewed in the Thermal Simulations list. Details of the simulation parameters can be viewed in the pane next to the thermal simulations list by clicking on a specific case.

¶ Circulating

If the selected mode is Circulating then the form allows users to enter the parameters required to create a Circulating thermal load case. Following inputs are required for this load case:

- Last Participating String: Select the last participating string from the drop down list. This string is already set and the subsequent hole section is being drilled.

- Hole TD: This is the bottom MD of the subsequent hole to be drilled after the last participating string.

- Static Bottom Hole Temperature: Static Bottom Hole Temperature (SBHT) is defaulted to the undisturbed temperature at the Hole TD.

- Circulating Flow Rate: Flow rate of the circulating fluid in gal/min and can not be zero.

- Drilling Fluid Density: The default fluid density is fluid corresponds to the hole section to be drilled.

- Pipe Roughness: The default value for pipe roughness is 0.002 in. User may change this entry.

- Flow Duration: This parameter is the total flow period of the production operation. It may be entered in hours, days or months. This is a required input field and may not be left empty.

- Ocean Current: Heat transfer in the riser can be modeled with a non-zero ocean current. The default value is 0 ft/s.

- Wind Speed: Wind speed in ft/s is required for the section above the sea level to the rig floor. The default value is 0 ft/s.

- Step size: This denotes the step size (in ft.) used for segmenting the string. This parameter defaults to 50 ft. This field cannot be empty.

- Drill Pipe OD: Enter a drill pipe outside diameter. Default diameter is 6.625 in.

- Drill Pipe ID: Enter a drill pipe inside diameter. Default diameter is 5.581 in.

- Drilling Fluid Plastic Viscosity: Default plastic viscosity (PV) is 45 cP.

- Drilling Fluid Yield Point: Default yield point (YP) is 1lbf/100ft2.

- Circulating Fluid Temperature: This is the fluid temperature at the surface.

- Drilling Fluid Type: Select one from oil based mud (OBM) and water based mud (WBM).

- Click OK to add the thermal operation or Back to go back to Add new thermal case window.

- Press Cancel to cancel out adding a new thermal operation or modifying the existing thermal case.

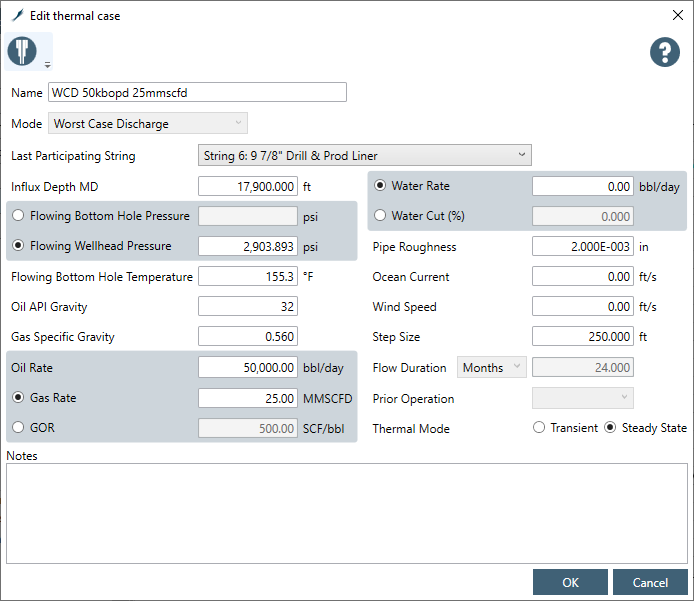

¶ Worst Case Discharge

If the selected mode is Worst Case Discharge (WCD) then the form allows users to enter the parameters required to create a WCD thermal load case. Following inputs are required for this load case:

- Last Participating String: Select the last participating string and flow is expected to come from the depth below this string.

- Influx Depth MD: This is the bottom MD of the subsequent hole to be drilled after the last participating string.

- Flowing Bottom Hole Pressure: One of the pressures (1) Flowing Bottom Hole Pressure (FBHP) or (2) Flowing Wellhead pressure (FWHP) is required. Both fields cannot be selected. The default FBHP is the pore pressure at the perforation depth.

- Flowing Wellhead Pressure: Default flowing wellhead pressure is the seawater hydrostatic at the mudline.

- Flowing Bottom Hole Temperature (FBHT): This input defaults to the undisturbed temperature at the perforation depth. The Undisturbed Temperature profile in the Temperatures tab under The Well Module. User can edit this input. This field cannot be left empty.

- Oil API Gravity: Specific gravity of oil of the produced fluid is defaulted to 32. This can not be empty or zero when a non-zero oil rate is expected.

- Oil Rate: Oil flow rate is in bbl/day and can be zero for gas only production. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- Gas Specific Gravity: Specific gravity of gas of the produced fluid is defaulted to 0.56 (as Methane). This can not be empty or zero when a non-zero gas rate is expected.

- Gas Rate: Gas flow rate is in MMSCFD and can be zero for oil only production. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- GOR: Gas-Oil-Ratio in SCF/bbl can also be entered instead of gas rate. In this case oil rate can not be zero bbl/day.

- Water Rate: Water flow rate is in bbl/day and can be zero. All three fluid rates (oil, gas and water) cannot be empty or zero at the same time.

- Pipe Roughness: The default value for pipe roughness is 0.002 in. User may change this entry.

- Flow Duration: This parameter is the total flow period of the production operation. It may be entered in hours, days or months. This is a required input field and may not be left empty.

- Ocean Current: Heat transfer in the riser can be modeled with a non-zero ocean current. The default value is 0 ft/s.

- Wind Speed: Wind speed in ft/s is required for the section above the sea level to the rig floor. The default value is 0 ft/s.

- Step size: This denotes the step size (in ft.) used for segmenting the string. This parameter defaults to 50 ft. This field cannot be empty.

- Click OK to add the thermal operation or Back to go back to Add new thermal case window.

- Press Cancel to cancel out adding a new thermal operation or modifying the existing thermal case.

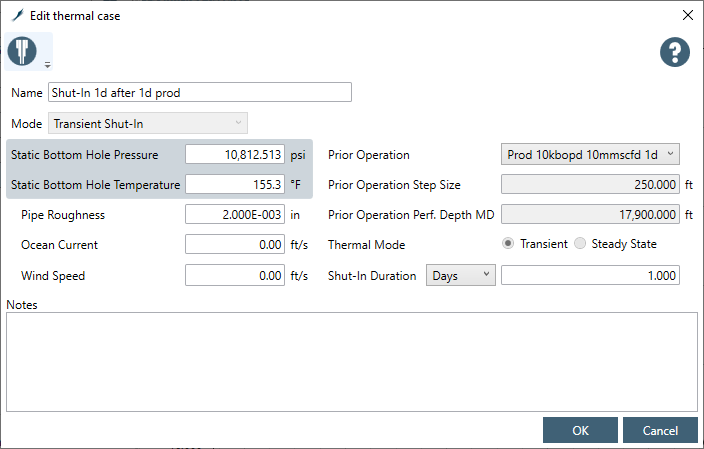

¶ Transient Shut-In

This is the Shut-In thermal load case. This requires a transient thermal operation such as production. Following inputs are required for this load case:

- Static Bottom Hole Pressure: The default SBHP is the pore pressure at the perforation (production) depth. The Pore Pressure profile in the Pressures tab under The Well Module. User can edit this input. This field cannot be left empty.

- Static Bottom Hole Temperature: This input defaults to the undisturbed temperature at the perforation (production) depth. The Undisturbed Temperature profile in the Temperatures tab under The Well Module. User can edit this input. This field cannot be left empty.

- Pipe Roughness: The default value for pipe roughness is 0.002 in. User may change this entry.

- Ocean Current: Heat transfer in the riser can be modeled with a non-zero ocean current. The default value is 0 ft/s.

- Wind Speed: Wind speed in ft/s is required for the section above the sea level to the rig floor. The default value is 0 ft/s.

- Prior Operation: This is a selection of a transient prior operation.

- Prior Operation Step size: This denotes the step size (in ft.) used for segmenting the string. This parameter defaults to 250 ft. This field is not editable.

- Prior Operation Perf. Depth MD: This is the perforation depth (for production and is the injection depth for injection thermal case) in MD. This field is populated with the depth given in the prior operation and not editable.

- Thermal Mode: Selection option for Transient or Steady State.

- Shut-In Duration: Select and enter a shut-in duration time.

- Click OK to add the thermal operation or Back to go back to Add new thermal case window.

- Press Cancel to cancel out adding a new thermal operation or modifying the existing thermal case.

¶ Calculate

With the Calculate Selected Cases(s) or Calculate All Cases buttons, the user can calculate the thermal simulations for all defined thermal cases or for a subset of the cases or even a single one. To select a subset of the cases, hold down the Shift key while selecting (for contiguous sets of cases) or the Ctrl key (for non-contiguous sets).

When the calculations are complete, the results of the first selected case are plotted on the chart on the right of this tab. Click on each calculated case to see its results.

To select which strings or annuli to view on the plot, click the Show/Hide Data button.

The right-click menu on the thermal case list table has the following options:

- Copy Case

- Delete Case

- Edit Case

- Copy selection as text

- Copy selection as text w/headers

- Copy table as image

- Font settings

The first three of these options are described in detail in the Working with Tables section.

¶ Simulation Results

Thermal results are displayed in the following tabs -