¶ Wellbore Containment Analysis (WCA)

The objective of this analysis is to demonstrate to Bureau of Safety and Environmental Enforcement (BSEE) that the well design and equipment are adequate for well containment in case of worst case discharge (WCD) scenario, i.e. to determine whether a well can be contained via a capping stack in case of a WCD scenario. The WCD considers unrestricted absolute open flow (AOF) from the productive zone to the seabed. WCA are performed in following levels:

Level 1 - It is required for each drilled hole section independently that has potential of hydrocarbon flow. Production strings are excluded unless they will be drilled out. Level 1 screening considers a very conservative approach. It is designed to expedite approval for wells that can be fully shut in without causing underground flow.

Level 2 - If the well does not pass a Level 1 screening then BSEE requires a Level 2 screening to confirm that the wellbore is still suitable for containment under the unrestricted flow and adequate for subsequent full shut in. This screening identifies failure points and possible loss zones that must be addressed in a consequence analysis.

StrinGnosis® currently supports the following worst case discharge (WCD) loads:.

- WCD Burst Level 1

- WCD Collapse Level 1

- WCD Burst Level 2

- WCD Collapse Level 2

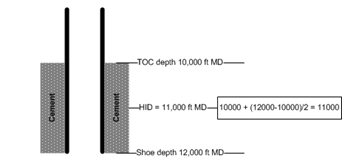

¶ Hydraulic Isolation Depth (HID)

The Hydraulic Isolation Depth (HID) is effectively the assumed top of good cement where hydraulic isolation is achieved in the annulus. HID is calculated based on the following assumptions:

- Casing shoe minus 50% of the planned TOC column height in MD.

- For a fully cemented surface casing, the TOC (i.e. ML) is the HID.

- For fully cemented liner, HID is the liner shoe minus 50% of the planned cement column height in MD.

¶ Hydrocarbon Fluid Gradients

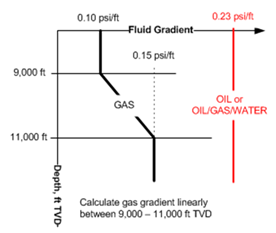

According to BSEE, the hydrocarbon fluid gradient (psi/ft) for Level 1 screening is assumed as follows:

- Only for gas production zones, 0.1 psi/ft for zones <= 9000 ft TVD, increasing linearly to 0.15 psi/ft for zones greater than 9000 ft TVD to 11000 ft TVD.

- For combined fluid production (oil, gas and/or water) the hydrocarbon fluid density is assumed as 0.23 psi/ft for the zone of interes.

- Advanced modeling and field/offset data for produced fluid gradient may allow the well to pass Level 2 screening.

¶ Trapped Annulus Screening

To pass the trapped annulus screening conditions (no trapped annulus), the evaluated string must be one of the following:

- A conductor/surface string fully cemented back to the mudline.

- A fully cemented liner or scab liner.

- A liner with a lap <= 500 ft that meets the following criteria:

- Has 500 ft measured depth (MD) between the planned TOC and the previous shoe, or

- Has a cement column height in MD <= 50% of the open hole length in MD.

- A casing or liner with a lap > 500 ft that meets the following three criteria:

- Has 500 ft MD between the planned TOC and the previous shoe, or a cement column height in MD <= 50% of the open hole length in MD.

- Has <= 30 degrees inclination in the annulus above the previous shoe (i.e., only consider casing X casing annulus).

- Has not been idle for > 1 year.

¶ Notes:

- Criteria a and b in item numbers 3 and 4 above are related to the potential for barite plug formation. Criterion a is related to the potential of cement sealing off the annulus.

- All scab liners (unless fully cemented) and tiebacks are assumed to have a trapped annulus for Level 1 screening, and will require a Level 2 analysis.

¶ Design Safety Factors

Both Level 1 WCD Burst and Collapse safety factors must be >= 1.0. The design safety factors for Level 2 also must be >= 1.0 although the operator may provide an explanation to allow a lower design factor. A few comments on BSEE's load and strength definitions:

- The collapse load is defined as external pressure minus internal pressure. It does not consider the internal pressure correction for string dimension, the factor (1-2t/D).

- "The tubular ratings must match the value for the casing ratings shown in BSEE eWell system for the APD/APM. For components other than tubulars, use the manufacturer's ratings."