¶ Tubing Shut In

Shut-In Tubing is a production burst load for the production tubing. Shut-In Tubing Pressure (SITP) is in the production tubing at the top of the tubing and is calculated as following – SITP = p@ perf − Cρprod(zperf−ztt) where,

p@ perf = pore pressure at the perforation depth, psi. Pore pressure at the perforation depth is obtained from the given pore pressure profile and that will be defaulted to the standard load.

SITP = shut-in tubing pressure, psi

zperf = true vertical depth of the perforation, ft

ztt = true vertical depth of the top of the tubing, ft

ρprod = production fluid density, ppg

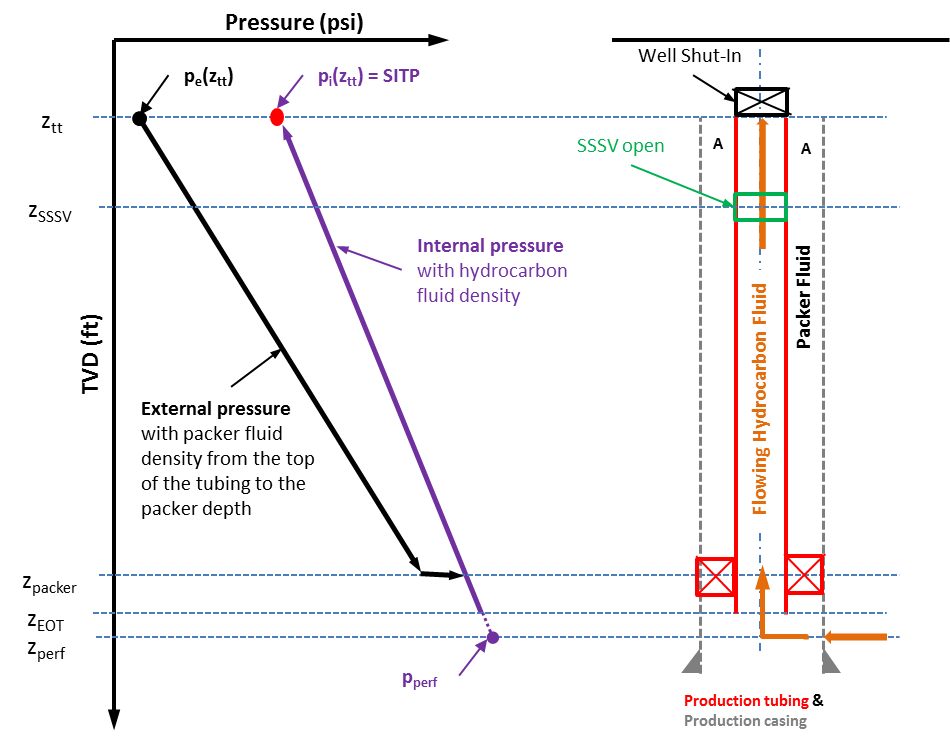

Shut-in tubing load case with casing and tubing configuration. Production tubing with packer is in RED. Internal pressure profile for the production tubing for shut-in tubing load case is shown in purple line. External pressure profile is shown in black line.

- Internal pressure assumes shut-in tubing pressure on production fluid density and is calculated as pore pressure at the perforation depth minus flowing fluid hydrostatic to the top of the tubing. pi(z) = SITP + Cρprod(z−ztt) where,

- pi(z) = internal pressure at the depth of interest, psi.

- z = true vertical depth of interest, ft

External pressure assumes seawater hydrostatic at the mudline (zero at the surface for wells other than offshore subsea wells), packer fluid density to packer depth and production fluid density below packer. If packer fluid type is Brine then there is no fluid degradation. Otherwise, if the packer fluid is water or oil based mud then assume base fluid density (8.33 ppg for fresh water and 7 ppg for oil). Tubing external pressure below the packer will have the same pressure as the internal pressure in that section of the tubing. Therefore, in the external external pressure profile there will be a pressure discontinuity at the packer depth.

- pressure at mudline (subsea well) pML = CρswzWB

- pressure from the mudline to the packer pe(z) = pML + Cρpacker(z−zML)

- pressure below packer pe(z) = pperf − Cρprod(zperf−z)

where,

- pML = pressure at mudline, psi

- zWD = seawater depth, ft. zWD = zML − zRKB

- zML = mudline depth, ft

- zRKB = RKB depth, ft

- ρpacker = packer fluid density, ppg. Defaulted to base fluid density for WBM (8.33 ppg) and OBM (7 ppg).

ρsw = seawater density, ppg. Default density is 8.6 ppg.

- Production temperature for hot shut-in and undisturbed temperature for cold shut-in

¶ Comments

For creating this load automatically following assumptions can be made as for default inputs –

- Perforation depth can be defaulted to the end of tubing (or 50 ft deeper)

- Pressure at the perforation depth can be defaulted to the pore pressure at the perforation depth

- Production fluid density can be defaulted to 2.5 ppg

- Calculation of SITP is needed in Shut-In Tubing Leak load case. In absence of the production tubing, the top of the tubing TVD should be replaced by the mudline depth for the offshore subsea wells and zero for the rest of the well types. This will be important for shut-in tubing leak load case for the production casing/liner or production tieback/liner which is discussed in the subsequent section.