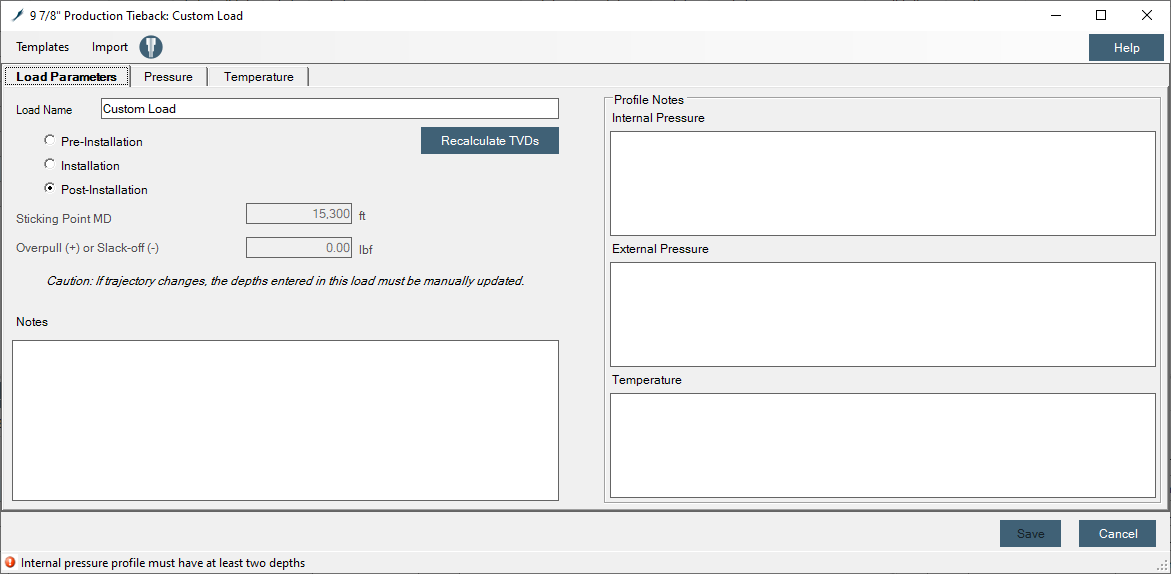

¶ Custom Loads

The custom load generator is a powerful tool that enables the user to consider load scenarios that don’t fit one of the provided standard load templates. Any load for a tubular can be created using the internal and external pressures and the temperature entered however the user wishes. Custom Load is available for all strings.

¶ Load Templates

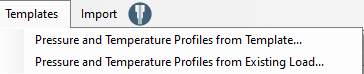

The user may also wish to create a load very similar to:

- a standard load or

- to an existing load (to the current string) as template and then modify its pressures and temperature profiles.

It is important to be aware that only the pressures and temperature profiles will be brought to the custom load from the standard and existing loads; any other parameters such as coefficients of friction or running velocity will be ignored.

Custom load will provide critical depths, pore and fracture pressures, undisturbed temperature and temperature from the thermal processor to all relevant tables. All those will also be editable.

The Custom Load, as it is a powerful tool allowing the user great freedom in designing a load, it is important to remember that, any changes to the wellbore architecture using the Casing Program Tab in the Casing Design Module or formation pressures and temperature in The Well tab are not automatically updated. Moreover, Custom Load can do very little checking of the validity of the inputs.

¶ Installation Modes

All three modes of installation (Pre-Installation, Installation and Post-Installation) are available. If an installation load is already been created for the string, then the Custom Load will not provide installation option. For the Pre-Installation and Installation modes, Custom Load makes two more fields available:

Sticking Point

Overpull (+) or Slackoff (-)

By inputting the TOC into the Sticking Point field, a value for overpull or slackoff, and selecting Installation as the descriptor, the well designer can specify an initial condition with overpull or slack off applied to the uncemented portion of the casing string.