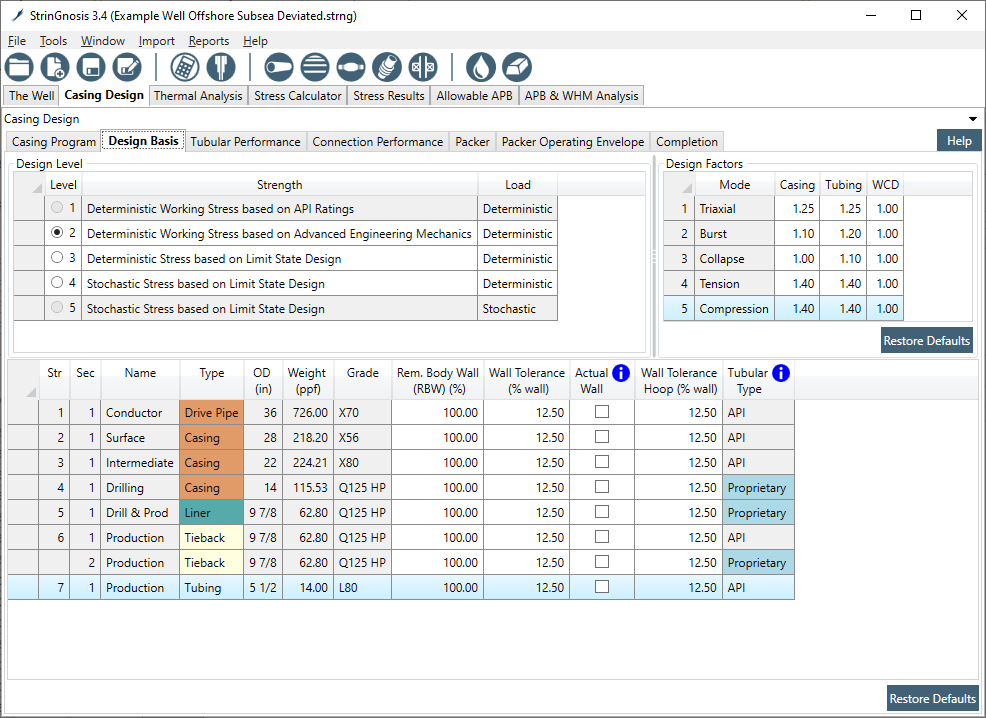

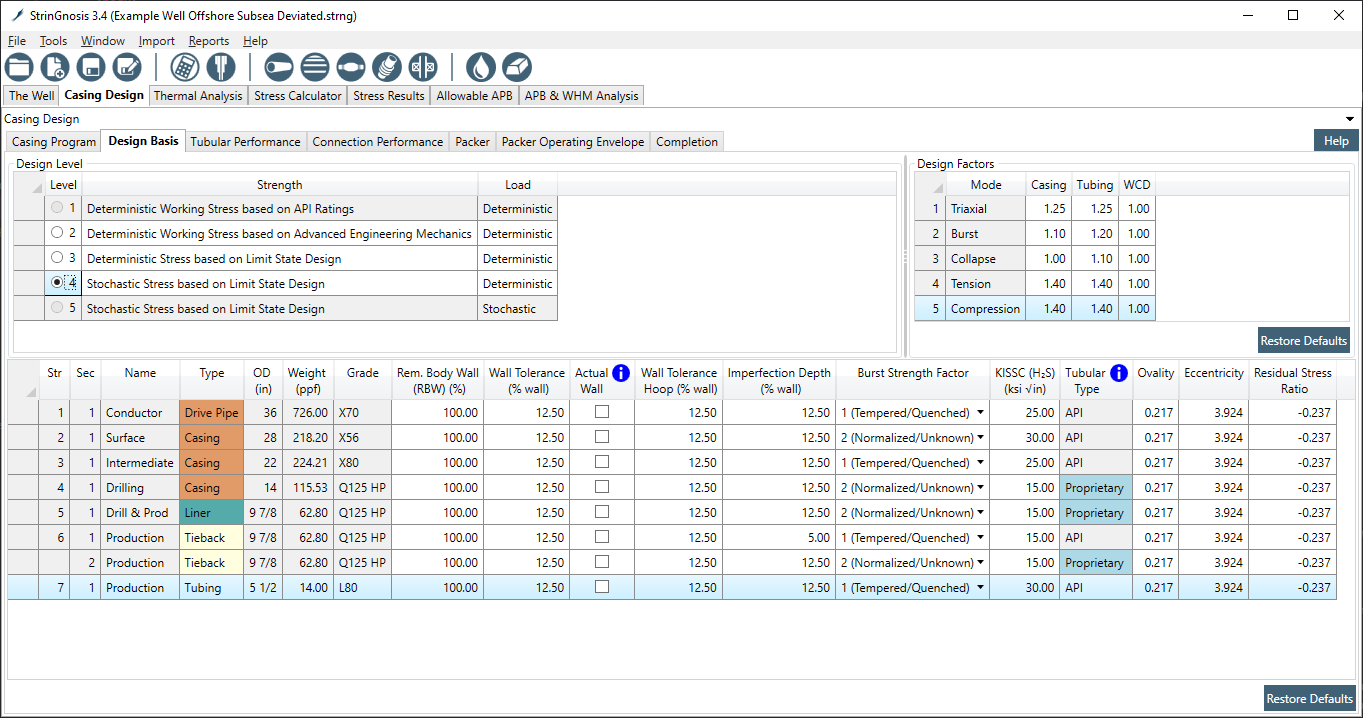

Design Basis

In the Design Basis tab, the user selects "Design Level" for the analysis and sets up other design criteria such as expected design safety factors, wall tolerance . The work flow in this tab will be as following -

- Select a design level

- Setup minimum acceptable safety factors. See Default Minimum Design Safety Factors are stated in S. Design factors can be set to their default values by selecting the Restore Defaults button.

- Make changes to any other parameters required in the tubular strength calculation in the bottom window

¶ Design Levels

Design Level 1

Design Level 1 might be employed to do a quick check of a non-critical tubular or to help select a weight and grade before continuing with a detailed design. It compares deterministic loads to uniaxial API strength formulas. It is not a comprehensive approach and is not recommended for use as the design of record for any well classification. The design criterion for a Level 1 design is simply that the SF, defined as the ratio of Capacity to Load is ≥ 1.00. Design Level 1 cannot be utilized in the software.

Design Level 2

Design Level 2 represents the most common approach to tubular design and is the industry standard for most well designs; the classical Working Stress Design approach. It compares deterministic loads to the API strength formulas and it considers combined load effects. This approach is recommended as the initial design approach to well design. The design criterion for a Level 2 design is the same as a Level 1 Design for the uniaxial loads. For the combined load effect, the Safety Factor is defined as the ratio of the Minimum Yield Stress to the VME Stress. In the event that the Level 2 design criteria are not satisfied, either a re-design or a more sophisticated approach is needed.

Design Level 3

Design Level 3 represents the first departure from the classical Working Stress Design approach. It utilizes a Limit State Function in place of the API Strength formula, for a given load case. The Level 3 approach is an estimate of the tube’s actual limit, assuming minimum strength parameters (, wall thickness, YP, etc…). The design criterion for any Level 3 design is simply that the tube’s utilization, based on the selected limit state, ≤ 1.00. This approach is foreign to many designers and, therefore, its use has been limited. Furthermore, as a wholly deterministic method, a Level 3 design still lacks a sense of how safe or risky it may be. To quantify this risk, we need a more sophisticated methodology. Levels 4 & 5 provide quantification of the risk.

Design Level 4

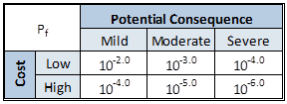

Design Level 4 represents the first method where the probability of failure is calculated. Like Level 3, it utilizes a Limit State Function, but statistical data for the various strength parameters are used in place of minimums. In doing so, a probability of failure can be calculated, given that the tubular is representative of the distributions used. StrinGnosis® uses distributions provided in ISO-10400. StrinGnosis® also utilizes proprietary distributions for parameters not included in ISO-10400. All distributions can be viewed on the Stress Results tab, under Safety Factors > Reliability > "Manage PDF Sources". StrinGnosis® also enables the well designer to define the strength parameter stributions, if the data are available. The design criterion for a Level 4 design is a Probability of Failure (Pf). Consideration of the consequences and the cost of a failure are accommodated by use of a matrix. This approach is recommended when the Level 2 Working Stress Design approach criteria cannot be met.

Design Level 5

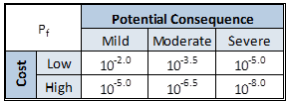

Design Level 5 is a full reliability based design. Like Level 4, a Level 5 design utilizes a Limit State Function with statistical data for the various strength parameters. It also replaces the conservative estimate of the load (deterministic load) with a probability distribution that describes the probability of occurrence and the likely magnitude of the load, should it occur. Stochastic load data is difficult to acquire and many regulatory authorities are reluctant to accept a stochastic load analysis. Therefore, the Level 5 approach is not used on a routine basis.

Like Level 4, the design criteria for a Level 5 is a Probability of Failure (Pf) selected on the basis of the consequences of the failure. In Level 5 designs, the addition of a load side Probability Density Function has the effect of increasing the over-lap area (Pf). As a result, a safe design will have a slightly lower allowable Pf. The determination of what is considered a Low or High cost and what Mild, Moderate and Severe consequences are the same as discussed in the Level 4 Design approach. Blade Energy Partners can assist with Level 5 designs, for specific loads.

¶ Other Design Criteria

Blade Technology does not make any recommendations regarding design criteria for Level 3 designs. Instead, a Level 4 Design methodology is recommended as it provides quantification of the design’s risk.

The design criterion for a Level 4 design is a Probability of Failure (Pf). Consideration of the consequences and the cost of a failure are accommodated by use of a matrix. Suggested maximum Level 4 Probabilities of Failure recommended for the various combinations of failure cost and consequences. These criteria are a matter for operating company’s management to determine.

Like Level 4, the design criteria for a Level 5 design is a Probability of Failure (Pf) selected on the basis of the consequences of the failure. Suggested maximum Level 5 Probabilities of Failure shows the suggested maximum Level 5 Probabilities of Failure recommended for the various combinations of failure cost and consequences. Level 5 design requires robust load side statistical modeling. These criteria are a matter for operating company’s management to determine.

The determination of what is considered a Low or High Cost and what Mild, Moderate and Severe consequences mean are the responsibility of the operating company’s management. Typically, the threshold between Low and High cost is the cost of the subject well. Similarly, a Mild consequence is typically one where the loss is limited to minor equipment damage with no lost time injuries. A Moderate consequence would typically be one where there is significant loss of equipment or one involving a lost time injury. A severe consequence would typically be on the order of the entire well or facility being lost or an instance where a fatality occurs.

¶ Tubular Strength Parameter Table

This table is at the bottom of the Design Basis tab and lists the casing strings of the design. Depending on the Design Level selected, a number of fields on the right side of the table become available for editing. To reset all these values back to the system defaults, click the Restore Defaults button.

¶ Level 2 Design Parameters

- Remaining Body Wall (RBW)(%)

- Wall Tolerance (% wall)

- Imperfection Depth (% wall thickness)

- Actual Wall (consider only RBW, disregarding wall tolerance, in burst SF calculations)

- Wall Tolerance Hoop (% wall)

- Tubular Type (API or Proprietary)

¶ Level 3 and 4 Design Parameters

- Burst Strength Factor

- Burst Strength Factor

- KISSC H2S (kpsi √in)

- Ovality

- Eccentricity

- Residual Stress Ratio